In Japan, mudslides and landslides caused by rain and earthquakes have resulted in the loss of many precious lives and property (houses, fields, public facilities and other items necessary for life and social activities). SABO is an erosion control to prevent and mitigate mudslides and landslides.

In Japan, where mountains occupy 70% of the national land area, valleys surrounded by mountains, fans opened downstream and gentle plateaus around volcanoes are used as places for daily life and industrial activities, and the technology of erosion control technology (=SABO) to protect such places has developed and spread remarkably in Japan. This is why the word “SABO” has become a world-wide term.

https://jsece.or.jp/general/sabo/

Cement and the recycling society

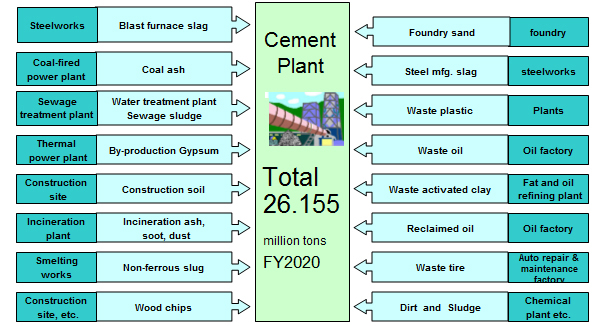

Cement, the raw material for concrete, is a recyclable raw material produced by taking on large quantities of incineration residues from municipal waste and other materials generated in large quantities every day, as well as industrial waste from thermal power stations, and making effective use of these materials.

Even today, as much as 475 kg of raw fuel is utilised to produce one tonne of cement, which plays a major role in extending the life of final waste disposal sites. As the cement industry is inherently energy-intensive, cutting-edge technological developments are constantly being carried out to promote even greater energy savings.

Cement also produces carbon dioxide during the firing process, but when it becomes a concrete product (alkaline), it absorbs carbon dioxide from the atmosphere, leading to progressive neutralisation. The cement industry is now globally interested in quantifying and standardising this characteristic.

Another property is that it is non-combustible and mineral. Concrete products made by mixing cement with sand and gravel are non-combustible and mineral, so they are easy to recycle and can be used as recycled material as concrete rubble when disposed of.

Cement is manufactured from domestic raw materials, such as recycled materials from Japan and domestic limestone. While supporting our lives, safety and lifelines, the company contributes to a sustainable, recycling-oriented society by promoting recycling, protecting natural resources, reducing transport energy and carbon dioxide emissions, and contributes to a sustainable, recycling-oriented society through constant technological development.

https://torii-cement.com/cementandsdgs/

Figure 1 Uses of wastes and by-products in Japanese cement industry

https://www.jcassoc.or.jp/cement/2eng/e_01d.html

Torii Cement Kougyou Co., Ltd.

Torii Kougyou Co., Ltd., established in 1954, is a company in Toyama Prefecture that has been planning, manufacturing and maintaining concrete tiles for many years, with ‘terrazzo tiles’ as its main product. With a system that can handle even a single original custom-made terrazzo tile, and expertise backed up by experience and technology, we are the only manufacturer in Japan specialising in terrazzo tiles and can respond to a wide range of tailor-made requirements.

We have also organised and stored data and actual samples of the formulations of all the more than 3,000 Terrazzo products it has delivered to date, and can reproduce even a single tile if it needs to be repaired or replaced due to damage or deterioration. This accumulated data and know-how enables us to reproduce as closely as possible even terrazzo tiles that are not our own products.

We collaborate in manufacturing, using our extensive experience and technical know-how to the SABO project.

https://torii-cement.com/